Gold and its alloys

Gold quality is usually defined by Karat, with each karat representing 1/24 of the amount of pure gold in an alloy as measured by weight. Thus, the the higher the karat, the greater the proportion of pure gold there is. The remaining content of an alloy consists of assorted elements that combine to strengthen, and provide color, or, in a few cases, act as correctives for the unwanted properties of other alloying elements.

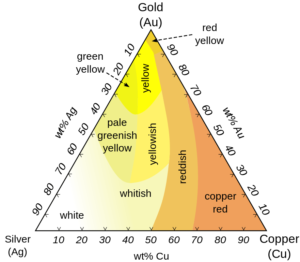

Pure gold in its natural state is a rich, almost buttery yellow, but when alloyed, it can be produced in a range of other colors. Yellow, white , green, and pink/rose golds are available as a bulk metals, which are uniform in color throughout an alloy. Some blue and purple gold are also bulk metals; they are very brittle and not commonly used as jewelry alloy.

Some black, and chocolate, and some other colors of gold are often products of the surface treatments and coloring, plating and coating. There are also blue and black golds that are the products of black rhodium and oxidation reactions rather than coating. these alloy contain, Ex., cobalt or iron, which greatly reduces ductility but also colors the gold during heat treatment. The three-metal alloy of gold, silver and copper, although other additions may be present. The combination of these three primary alloys can, in varying proportions, create yellow, pink, and green golds. Lower karat golds allow more color options than higher karat ones simply because the lower the karat, the greater the percentage of other metals that can be added to the mixture.

Although white gold appears as a color in the chart above, the high percentage of silver makes these white golds less than 10K, which is not recognized as gold in the United states. In the United Kingdom, a 9K alloy containing 37.5 percent gold and 62.5 percent silver is recognized as a small amount of the silver may be replaced with 3 to 5 percent copper for added strength. This alloy can be used for items of jewelry and is suitable for stone setting.

The most frequently used white gold alloys are created with nickel or palladium. Nickel has been the typical bleaching agent for white gold, but widespread nickel sensitivity is changing that. Because of the sensitivity, nickel content is closely regulated in the Europe Union. The wider effect is that nickel content of gold alloys has been reduced. However, the less nickel there is in an alloy, the more yellow-gray the alloy will be, and so rhodium plating. Degree of whiteness, or more accurately, paleness for white gold have not been standardized. Guideline for the disclosure of rhodium plating to consumers have also not been formalized.

Alternative to nickel white gold alloys have been and are being developed. Palladium white gold can be completely free of nickel; these white golds are also likely to be more expensive than the nickel whites.

Karat Min% gold Common alloying elements

24k 99.95 not applicable

22k 91.67 copper, silver, titanium

18k 75.00 copper, silver, nickel, pal, plat, zinc

14k 58.33 copper, silver, nickel, pal, zinc, silicon

10k 41.67 copper, silver, nickel, zinc, silicon

9k 37.50 copper, silver, nickel, zinc, silicon